By Adam Freill April 17, 2023

Heavy machine well suited to low-level buildings, bridges and industrial demolition work. Cylinder Head Assy

Engineered to be rugged for use in demanding applications, the Cat 352 Straight Boom Excavator is designed specifically for low-level demolition work up to five storeys high, bridges and industrial infrastructure. Its stick/boom configuration delivers a vertical reach up to 12.85 m (42’2”), 36 per cent more stick pin height compared to the company’s standard 352 reach configuration.

Working with up to a 6,000 kg (13,228 lb) attachment weight, the machine features standard Cat technologies for versatility, precision and efficiency in both demolition and excavating applications.

The company says the excavator’s optional 11.35-tonne (25,022-lb.) removable counterweight design increases transportation efficiency and lowers transportation costs. The mechanical variable gauge undercarriage has a 2,990 mm (9’10”) transportation width when needed and extends 500 mm (19.7”) in working mode to increase stability. Its new high-efficiency hydraulic fan features standard automatic reverse to keep the cores free from debris and reduce maintenance time.

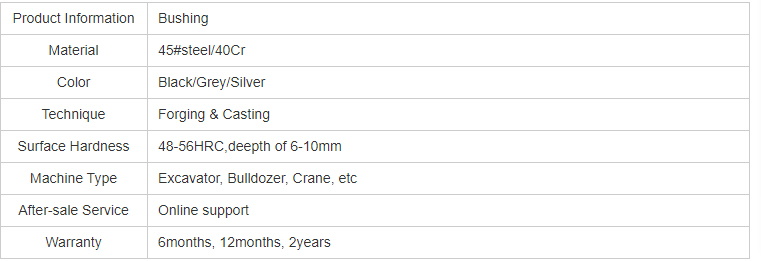

Designed for demolition, the 352 Straight Boom features reinforced booms, sticks and frame. Standard Falling Object Guards (FOGS) protect the roof and front reinforced P5A laminated windows from falling debris during demolition, while helping to maintain visibility of the jobsite. Sloped to prevent mud and debris accumulation, the track frame design helps to reduce track damage, while sealed track pins and bushings reduce travel noise and help to increase undercarriage life. Full track guiding guard is also a standard feature.

Additional features include Operator ID for push-button engine starting and programmable joystick functions that are remembered when the operator enters their unique ID. Standard Cat Stick Steer aims to simplify excavator movements with single-hand and push-button operation of travel and turning. Automatic power increase is available when needed, and standard auto dig boost aims to deliver better bucket penetration, shorter cycle times and greater payloads. Auto heavy lift offers additional lifting power when needed for as long as needed. Cat Lift Assist makes the operator aware that the load is within the excavator’s safe working range to avoid tipping.

Standard Cat technologies to elevate operating efficiency include Cat Grade with 2D that displays depth and slope on the 10-inch in-cab touchscreen monitor. When excavating, Cat Payload offers real-time, onboard weight estimates to help achieve precise load targets. Payload can be combined with VisionLink for remote management of production targets, while Cat Product Link provides machine operating data like location, hours, fuel usage, productivity and diagnostic codes to help increase jobsite efficiency and lower costs.

To easily detect objects and personnel around the operator in a single view, the 352 Straight Boom comes standard with rearview and right-hand-sideview cameras, which can be upgraded to provide 360-degree visibility.

The 352 Straight Boom features an electrohydraulic system and is powered by a 330-kW (443-hp) Cat C13B engine. Standard on the machine are a quick coupler, and medium and high-pressure circuits. Three engine power modes – Smart, Power and Eco – help to match engine and hydraulic power to the task at hand to further reduce fuel consumption and costs.

The excavator also offers remote diagnostics and updating capabilities.

Pin Bucket Construction technology is advancing both on and off the job site. On-Site goes in-depth on the latest steps forward in its Technology Report.